Soot filter for ships

A soot filter for ships removes soot from exhaust gases as they leave the exhaust pipe. A soot filter helps keep the deck and the water around the ship cleaner because the soot remains trapped in the filter.

In this article we explain how soot filters for ships work.

Regenerating the filter

Soot particles in a ship’s exhaust stream can be filtered out by a ceramic soot filter. The amount of soot each filter can absorb depends on its volume.

This means that every so often, the soot that accumulates in the filter has to be burned off to regenerate the filter. This also ensures that the exhaust back pressure does not exceed the maximum limit for the engine.

Different types of soot filter systems for ships

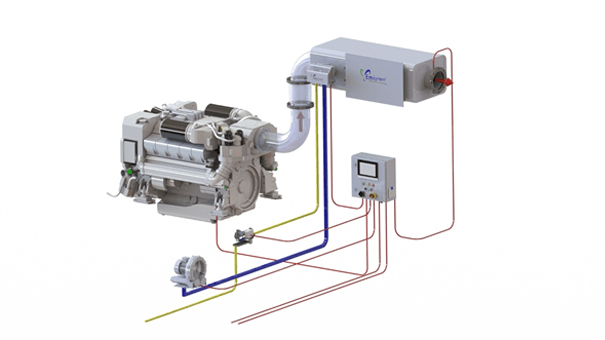

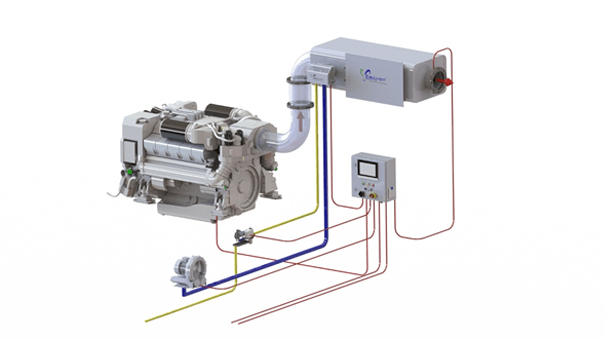

A soot filter for ships, otherwise known as a diesel particulate filter (DPF), removes soot particles from the exhaust gases produced by the ship’s diesel engine.

There are two different types of filter systems for ships:

- Passive filter systems.

- Active filter systems equipped with a fuel burner to actively initiate filter regeneration.

A soot filter removes up to 99% of the soot particles from the exhaust gases.

The need to regenerate the filter

Over time, the ceramic soot filter gets clogged with soot.

This soot has to be burned off to regenerate the filter. If the load on the engine heats the exhaust gases above a certain minimum temperature 80% of the time, there is little risk of the filter becoming clogged. In this case, a self-regenerating filter might be worth considering.

Excessive exhaust back pressure reduces engine performance and leads to (far) higher fuel consumption than is necessary.

Periodic removal of the ash (left in the filter after the soot is burned off) prevents loss of engine power resulting from high back pressure.

The difference between active and passive filter regeneration

All active soot filter systems for ships basically work the same way: they increase the temperature in the system. This ensures that the soot is burned off and regenerates the filter.

The difference between active and passive soot filter systems is temperature control:

- Active soot filter systems artificially raise the temperature within the DPF.

- Passive soot filter systems do not need additional heat because the engine produces exhaust gasses at a higher temperature.

Passive soot filter systems reach higher temperatures simply with the heat of the exhaust gases. When smaller engines operate at sufficient load, the exhaust gases are often hot enough to burn off the soot.

If the exhaust gases are not hot enough to incinerate the soot, an active soot filter system ensures that the soot is burned off.

An external fuel burner provides the additional heat needed to convert the soot particles to ash.

The unique Emigreen® soot filter

Emigreen® is market leader in exhaust gas aftertreatment systems and supplies soot filters for ships, yachts and industrial applications.

Our soot filter differs from other systems in terms of its sophisticated control and user-friendly maintenance.

What makes the Emigreen® soot filter unique?

- With proper maintenance, the Emigreen® soot filter has a surprisingly long lifespan and is operated by a sophisticated control system that makes sure the engine will keep running and providing power.

- It can be maintained by the crew.

Our products are designed for ship owners, shipyards and engine manufacturers who want to install the most reliable systems on their ships and next to their engines.

The Emigreen® soot filter has minimal impact on the sailing schedule and enhances the experience of the yacht owner or charterer.

Meer informatie: https://www.emigreen.eu/soot-filter-for-ships/